RELATED PRODUCTS

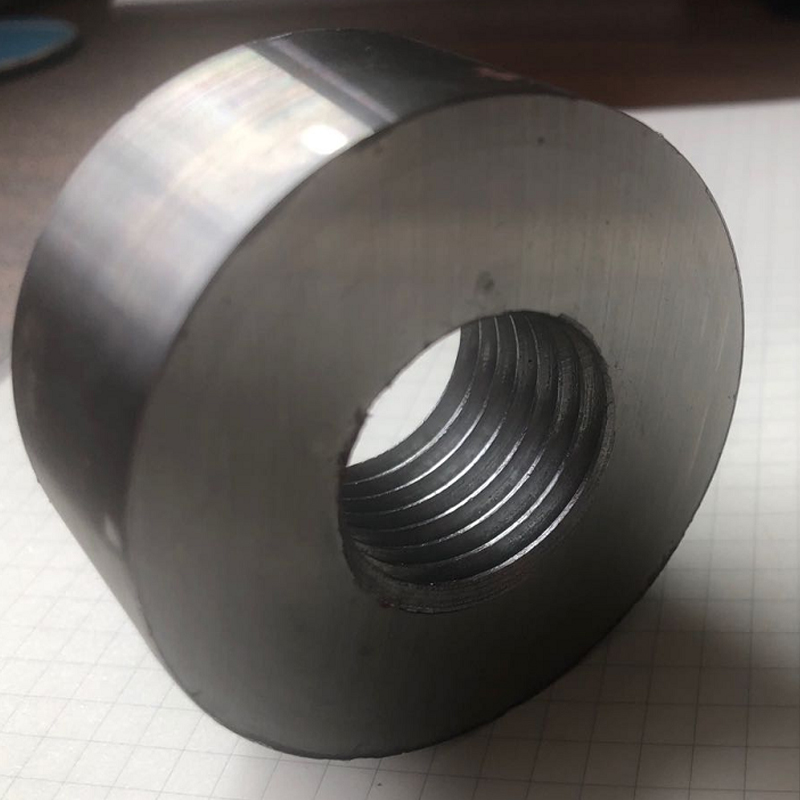

CNC Parallel Threading Rebar Coupler Product Characteristic 1.Material: 45#carbon steel, 40Cr2.Thread Pitch: 2.5, 3.03.Tread angle: 60, 754.Standard : HRB400, HRB5005.Craft: Tapping craft( normal); CNC Craft Product Picture

CNC Parallel Threading Rebar Coupler

Product Characteristic

1.Material: 45#carbon steel, 40Cr

2.Tread angle: 6°, 3°

3.Standard : HRB400, HRB500

4.Craft: CNC Craft

Product Picture

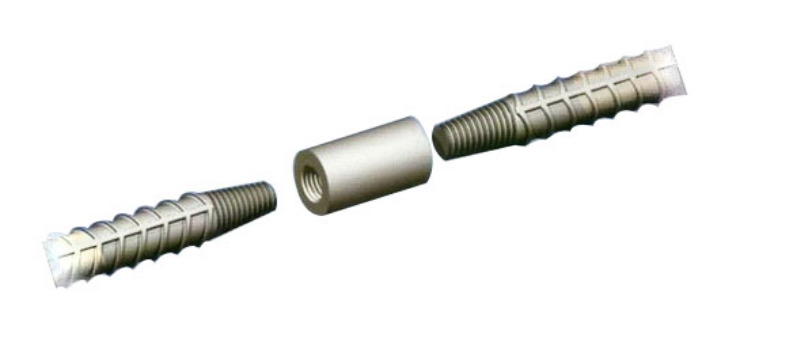

Standard taper threaded coupler

Position Taper threaded coupler

Transition Taper threaded coupler

Introduction: Taper threaded coupler is a kind of mechanical joint with internal tapered thread, which can withstand the axial force and horizontal force at the same time. It is used for rebar mechanical splicing in the concrete structure. It can connect re-bars of same or different diameter laterally, vertically and slantingly. It is broadly applied to the tunnel, tower, bridge, subway, airport, nuclear power station, high rise building and more..

Product Advantage:

1.Raw Material -Saving,high energy saving,high work efficiency.

2.Construction Environmental Protection, no frame, no noise pollution.

3.It is not be effected by the chemical composition and types of reinforced bars and won’t be influenced by weather and work-site.

4.Low cost, simple operation

5.Can be prefabricated and the construction period can be shortened

6.High dimension precision,reliable quality and stable performance.

7.High strength. The tensile strength usually more than 600 Mpa, it can reach 110% of yield strength of parent rabe.

8.After 2 million times of fatigue strength test, the connection is in good condition.

9.According to the inspection of National Construction Quality Supervision and Testing Center, the rebar coupler joint performance has reached the Grade I splicing rebar joint of JGJ107-2016 Industry Standard.

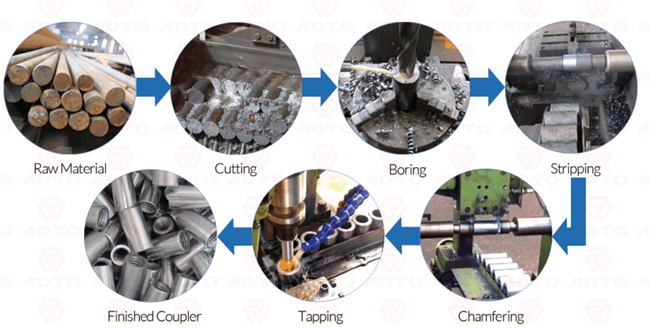

Production Processes

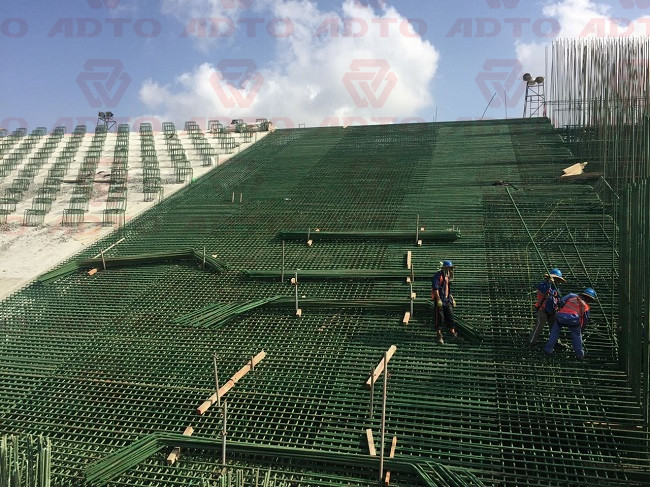

Projects