RELATED PRODUCTS

Upsetting forged rebar couplers offer a full strength connection together with enhanced fatigue resistance.

UPSETTING FORGED REBAR COUPLER

Upsetting forged rebar couplers offer a full strength connection together with enhanced fatigue resistance. They are suitable for projects of any size, including those requiring a high volume of couplers, such as road and rail bridges. Each end of the rebar to be joined is cut square and enlarged using a cold forge process. A thread is then formed on the enlarged bar end using a thread rolling machine. The thread is such that the cross-sectional area of the bar ends are not reduced ensuring the strength of the connection matches or exceeds that of the parent bars.

Product Characteristic

1.Material: 45#carbon steel, 40Cr

2.Thread Pitch: 2.5, 3.0

3.Tread angle: 60°, 75°

4.Standard : HRB400, HRB500

5.Craft: Tapping craft( normal); CNC Craft

Product Advantage:

1. No reduction of bar cross-section area and bar –break feature

2. No torque wrench required

3. Assembly validated by visual inspection

4. Standard ISO parallel Metric Thread Design.

Product Picture

Precessing Steps:

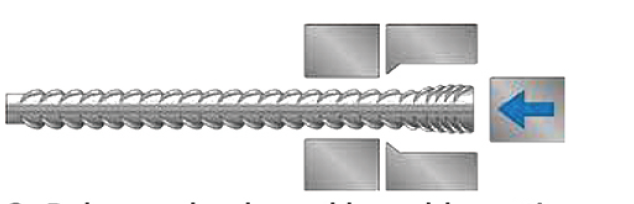

Step 1. Cutting the rebar end to make it flat

Step 2. Enlarging ends of reinforced bars by cold upsetting (Rebar Upset forging Machine )

Step 3. Threading parallel threads rebar end by DLADTO Rebar Thread Cutting Machine

Factory Picture

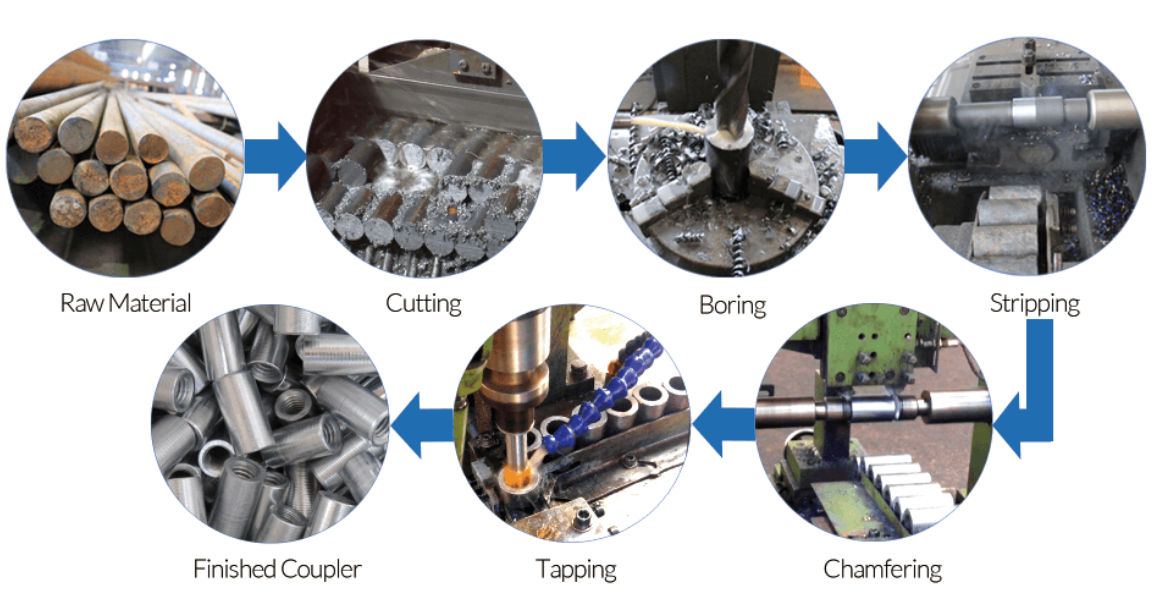

Production Processes

Package & Shipping