RELATED PRODUCTS

Steel bar thread rolling machine is mainly used for rolling straight threaded head of ribbed steel bar in construction engineering. It is the key equipment for realizing straight threaded connection of reinforced steel bar.

Steel bar thread rolling machine is mainly used for rolling straight threaded head of ribbed steel bar in construction engineering. It is the key equipment for realizing straight threaded connection of reinforced steel bar.

The steel bar rolling thread connection technology is suitable for industrial and civil buildings. Its process is simple and fast, no open flame operation, no pollution to the environment, no explosion fire hazards, safe and reliable, and can be constructed around the clock, saving a lot of steel and energy. Only a spanner is used to connect the steel bars, and each steel bar joint is about one minute, which shortens the construction period and realizes industrialized and civilized construction.

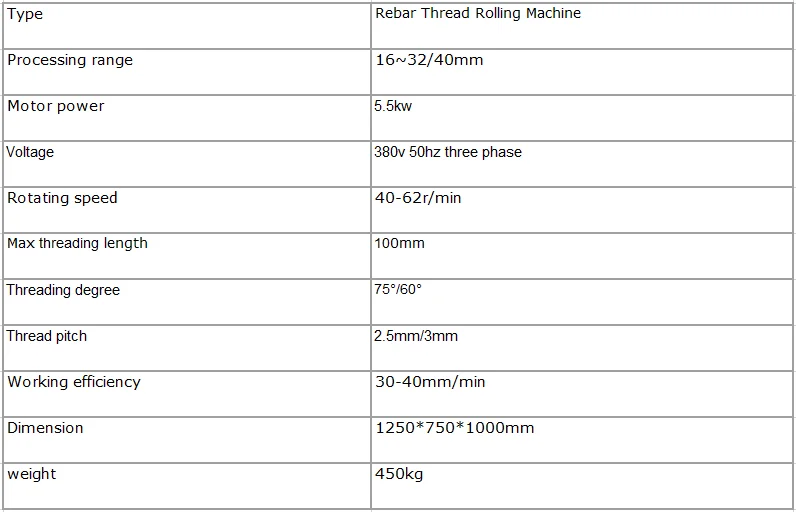

Technical Data

Machine Main Features

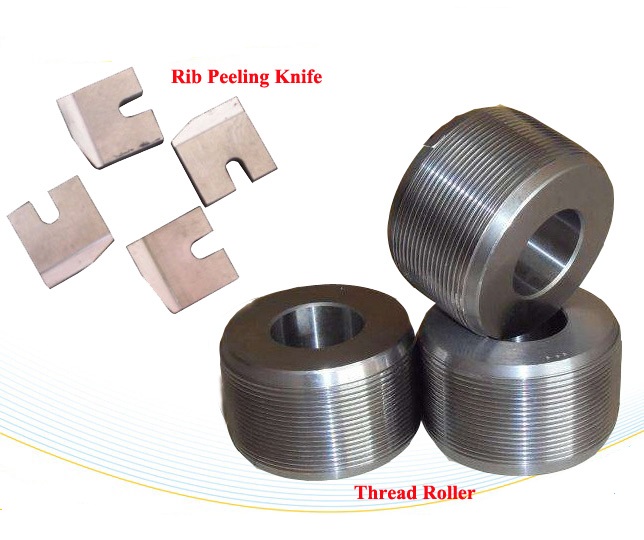

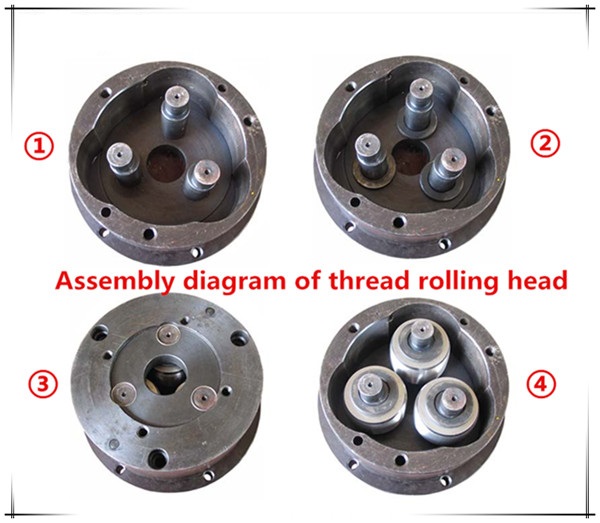

1. Rib stripping and rolling thread can be processed in one clamping.Full processing tooth shape, high dimensional accuracy.

2. Machinable positive and negative thread.

3. The machine is simple to operate, compact in structure, reliable in operation, and has a unique automatic cutter opening and closing mechanism.

4. The strength of the wire head is higher than the strength of the base material without cutting the base material of the reinforcing bar.

5. Wide application range, can process ribbed steel bars with diameter of 16 - 40.

Technical Advantages

1) High splice strength, which could exert ultimate tensile and compression strength of rebar, it could satisfy the requirements stipulated in the Chinese standard JGJ107, American standard UBC1997, British standard BS8110, French Standard NF35-20-1, German standard DIN1045, ISO15835 and other requirements in the relevant standards;

2) Easy to operate and maintain, no need for technicians, fast splicing on construction site;

3) Several types of splices, which could be suitable for rebar splicing when the rebar cage or the bending rebar is used;

4) High production efficiency, it only takes less than 1 minute to upset and make one thread on the site;

5) High adaptability, the splicing could be conducted when the power is off, or under water, or at super high position, or windy, rainy and snowy weather.

6) Environment-friendly, material-effective.

7) Inexpensive to purchase, maintain and repair.

8) The Splicing could be produced in advance without influencing the construction period.

9) Full-Tension splice, bar break under tensile tests.

10) Manufactured under strict quality assurance plan ISO 9001

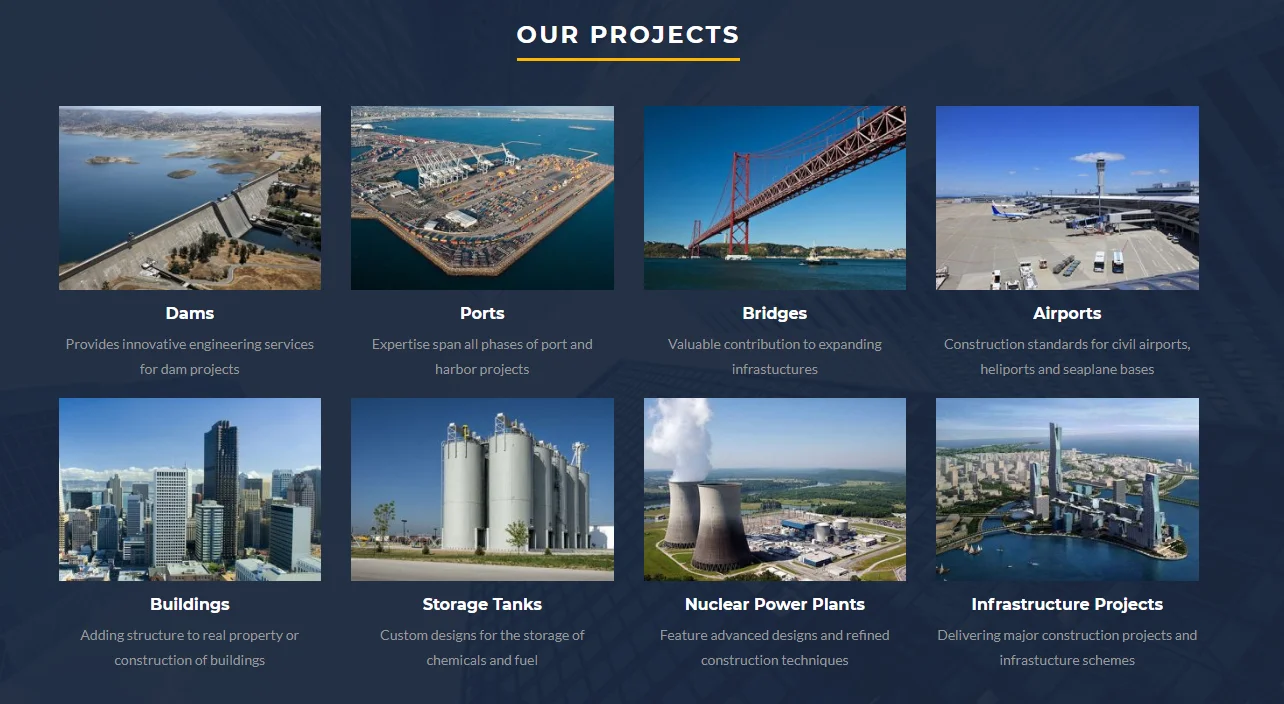

Application

Our main products are Rolling Parallel thread rebar coupler series (standard rolling parallel threading rebar coupler, upsetting rolling parallel rebar coupler, position rolling parallel threading rebar coupler; transition rolling parallel threading rebar coupler) ; Cold extrusion press coupler series; Grouting rebar coupler series; Weldalbe rebar coupler series; Special Shaped coupler etc, and also can provide customized service for customers.

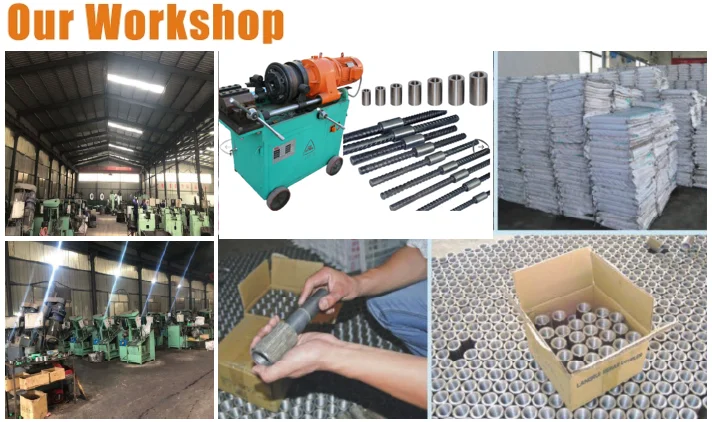

Our production base is located in Changsha covered 15000SQM and our annual production capacity comes up to 200000pcs/day.

“Security, high quality, high-efficiency “is our eternal faith, our products had exported to more than 40 countries and areas in the past 25 years. In domestic, we have many regular partners, such as MCC,CSCEC,CRCC,VANDA PLAZA etc.

Packing

EHXIBITION

FAQ

1.You are a manufacturing company or trading company?

---We are a metal alloy manufacturing and we have years of export experience. we have a reasonable price.

2.What quote do you offer?

---FOB , CIF and others ways according the your needs.

3.What is your terms of payment?

---TT. PAYPAL .L/C

4.Can I order a small list ?

---Of course,you can.

5. How long is your delivery time ?

---Generally it is 7days if the goods are in stock or it’s 12-15days if the goods are not in stock , all depends on the quantity .

6.What else related accessories do you also supply ?

---. Yes,such as :Blade\Thread roller\Spanner\Torque wrench\ Thread head\Eccentric shaft...